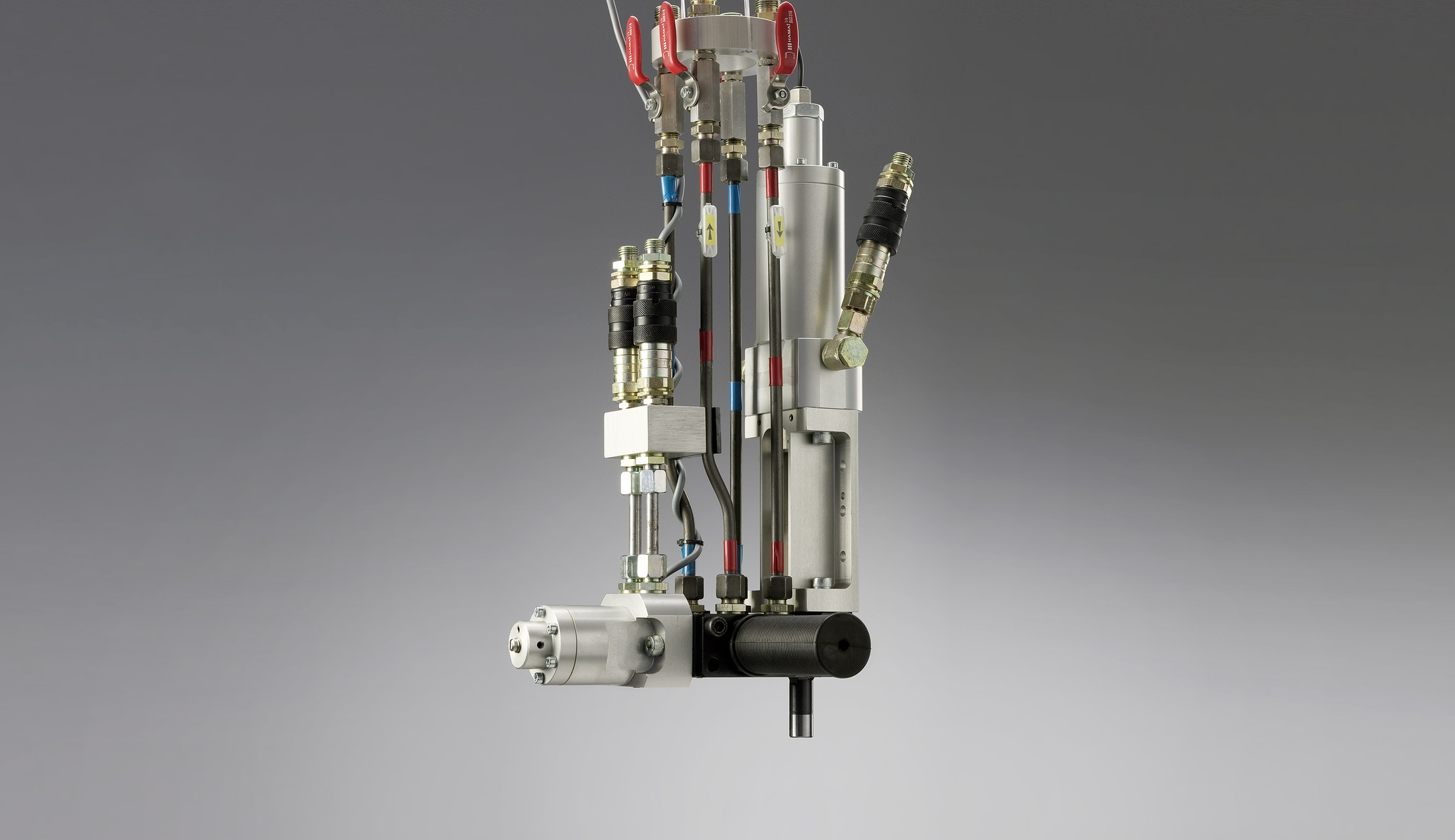

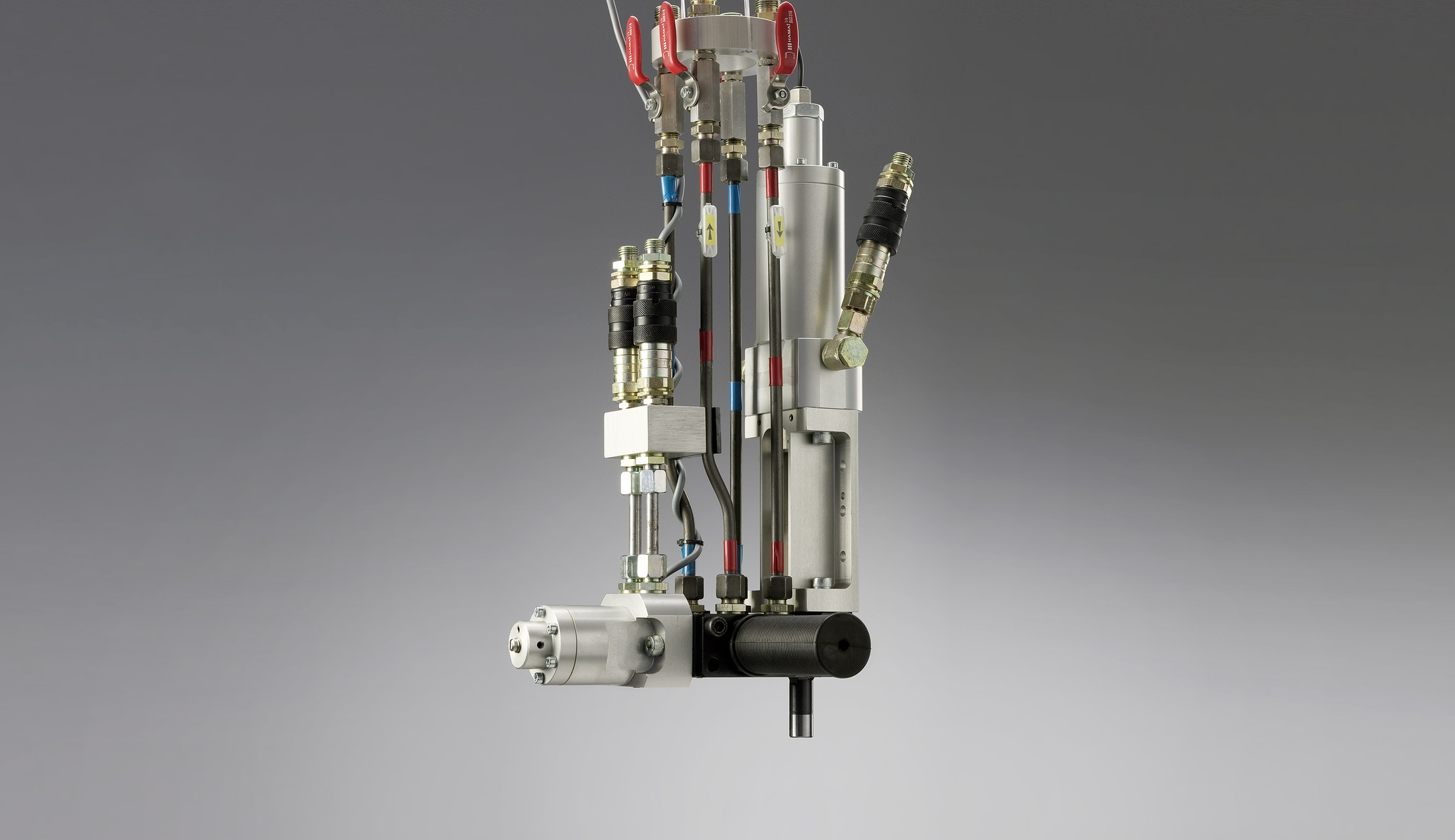

GP600

The modular GP600 L-shaped mixing head allows for the smallest lead-free single shots before and after, as well as continuous ejection during casting with maximum repeatability.

The modular GP600 L-shaped mixing head allows for the smallest lead-free single shots before and after, as well as continuous ejection during casting with maximum repeatability.

When the mixing chamber is closed, the components circulate through the mixing head, back into the process vessel. This results in optimum temperature, viscosity and pressure stability. The shot is mixed according to the high-pressure impingement principle and is ejected via an L-shaped head in a splash-free and laminar manner. When the shot is completed, the residual mixture is mechanically ejected from the mixing chamber and L-shaped head into the tool. This means that even highly reactive systems with pot lives of less than 2s can be processed.

Enables splash-free, leak-free casting into open molds and injection into closed molds.